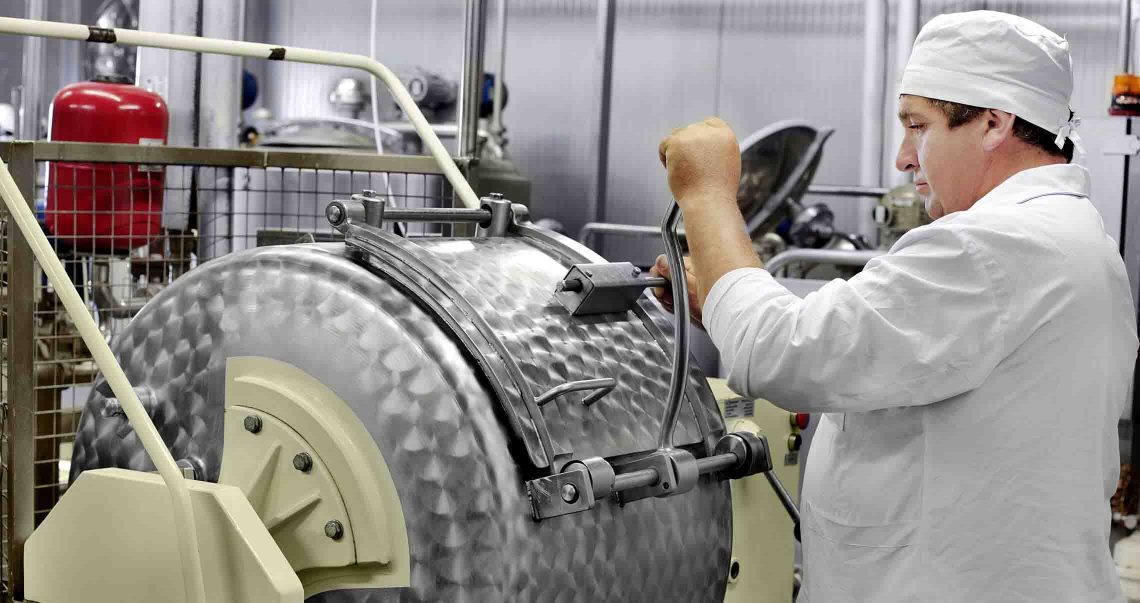

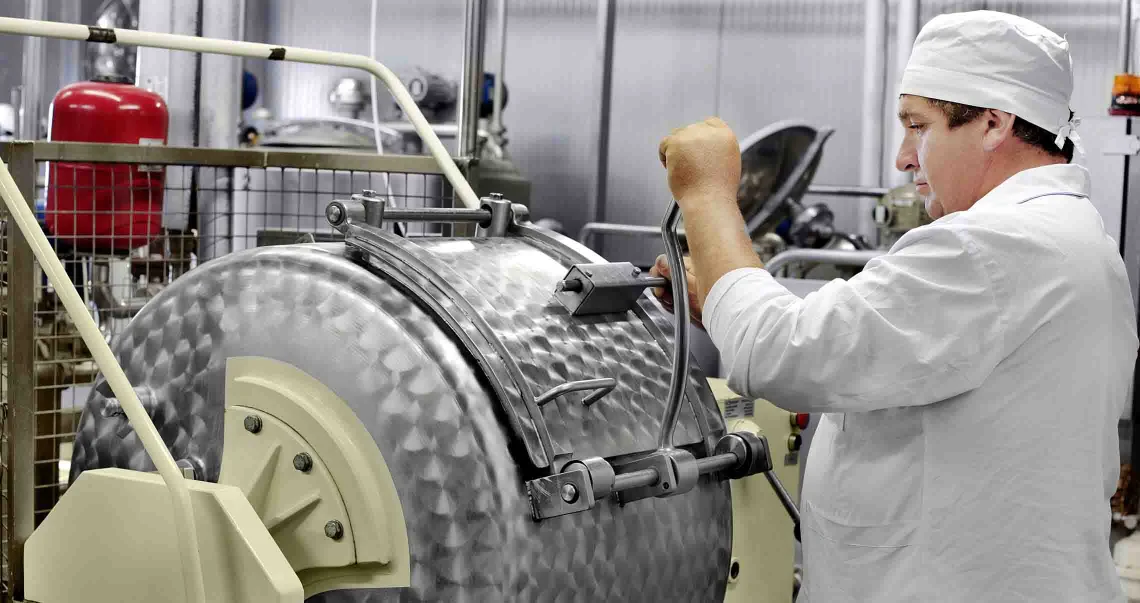

Quality control in the food and beverage industry: Don't cut corners

Food and beverage is a multibillion-dollar industry—but it's also a highly competitive field, partly because the barrier to entry for new companies is lower than in many other sectors. While efficiency is key to making the margins work, manufacturers can't afford to cut corners on quality control.

Companies should ensure their procedures and efforts are strong while keeping their operations streamlined and adapting to challenges. Efficient quality control in the food and beverage industry is about good supply chain management practices and cross-operational visibility.

Understanding the risks

Food and ingredients must adhere to strict FDA health and safety regulations, with tighter restrictions on food that's offered for sale in interstate commerce. Your business may also be subject to rules about facility preparation and allergens disclosure. Non-compliance means facing penalties and legal action—especially if a customer becomes ill after consuming your product.

Between 2022 and 2023, the Centers for Disease Control and Prevention, or CDC, estimated one in six Americans fell ill each year due to contaminated food. They also stated that around 3,000 Americans die annually because of various foodborne illnesses. Good quality control can help to reduce those numbers significantly.

By focusing on quality, you also protect your brand reputation. Today, customers can easily take to social media to share bad experiences, leave negative reviews or post complaints on your social network pages. Word can spread quickly, and unsatisfied customers could harm your business and sales.

Putting strict quality control measures in place will also help protect your profits. Waste due to poor quality will increase your costs, while quality measures protect your investment and can increase orders. If a defective product reaches the consumer, your costs to manage a recall could be much higher than if you'd remedied the issue at the source.

Best practices for quality control

Food and beverage products can go through a variety of stages in the supply chain, from ordering and receiving ingredients to the production and shipment and delivery to end users. Overlooking the quality in any of these steps can result in low quality or even bad products. Instead, manufacturers should take steps to optimize their efforts around quality control in the food and beverage industry.

First, set strong expectations around quality, and ensure that every member of the team understands and is committed to it. Define metrics you'll adhere to, and make quality a part of your mission.

Use your standards as a way to vet and select vendors. To protect your company, you'll want to make sure every partner that becomes part of your process has the same commitment to delivering high quality.

Also, use expectations as part of your hiring process. Any employee who has access to food or beverage during production must be able to follow your quality assurance protocols. You should also have an employee or team assigned to monitoring your product and comparing it against your quality measures. For good measure, set up a process for safe, efficient disposal in case your product doesn't meet these guidelines.

Smarter food and beverage safety measures

Prevention is often the best metric of quality control. The 2020 New Era of Smarter Food Safety initiative by the FDA outlines a proactive blueprint for better food safety measures. It includes four elements:

- Technology-driven traceability: Enable supply chain food traceability and track outbreaks with more ease with technological innovations.

- Outbreak response tools: Predict future outbreaks with predictive analytics.

- Food safety culture: Encourage and promote food safety through cultural awareness.

- Retail modernization: Integrate food safety and online service by bring the supply chain up to speed on best practices.

If your products have any quality issues, take steps to find the root cause. Collecting data throughout the process can help you better prevent future quality issues. You may want to invest in quality assurance software that can help track and analyze your supply chain and manufacturing process and flag potential issues. Data can provide transparency and information you can use for accountability and continuous improvement.

In addition to the FDA's blueprint, food manufacturers and distributers can follow the practical technical suggestions from the EPA in regard to food manufacturing pollution prevention techniques. Many of these techniques can help facilities reduce water, chemical and energy use, operate more efficiently, and save money.

The bottom line

Quality assurance isn't just a box to be checked off when you first establish a manufacturing process for your food or beverage product. It must be an ongoing and vigilant process, and it deserves your business's full commitment. By focusing on quality, you can also focus on delivering the best consumer experience. The return on investment can be a growing base of happy, loyal customers.